The project focuses on the development of a new generation of stiffened thermoplastic composite products that are lighter, more durable, and cost-efficient to produce. The use of thermoplastic composites (reprocessable and meltable) overcomes the limitations of thermosets. This creates the prospect of circular and scalable production for sectors such as air and road transport, energy, and consumer goods. The ultimate goal is integrated, serial production with lower CO2 emissions, less material waste, and greater design freedom for SME applications.

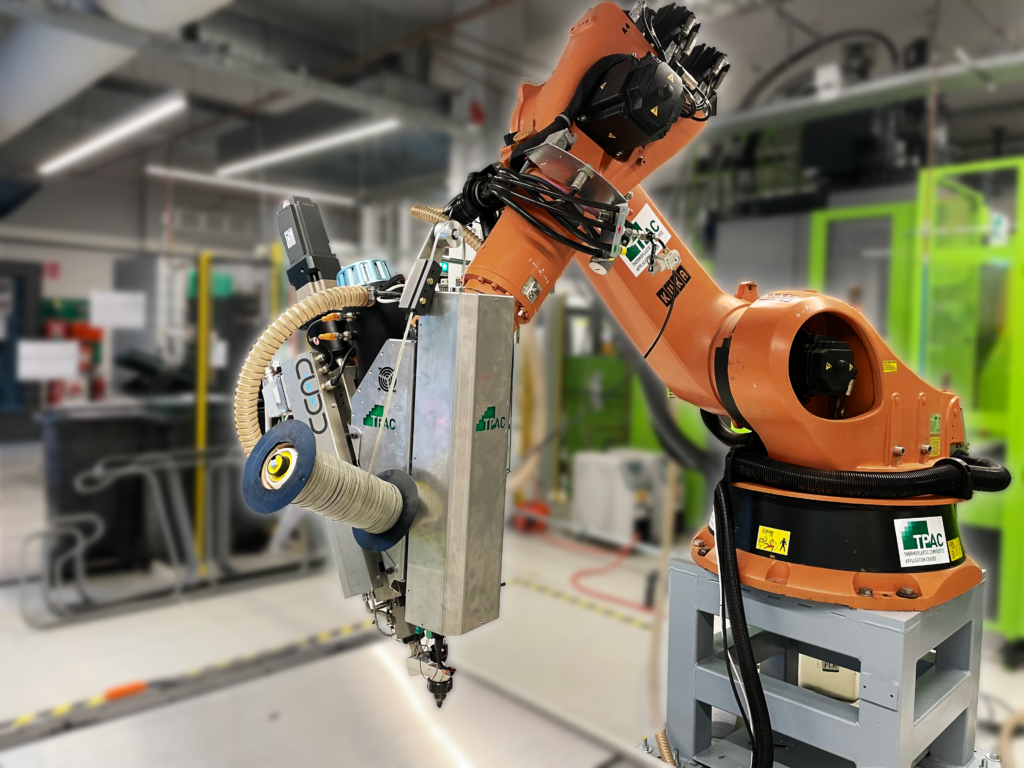

Prototype setup for 3D printing large, fiber-reinforced thermoplastic parts.

Approach

The core is a smart combination of production techniques. Largeformat 3D printing is coupled with in-line pultrusion, where continuous fibers are immediately incorporated during printing for added strength. TPAC develops and integrates everything necessary: process knowledge, custom-designed hardware and controls, robotics, and peripherals. Cost-effectiveness is paramount. In addition to technology, there is a focus on knowledge sharing through education, publications and conferences.

The four-year project is in its final year: implementation and validation. The focus is on improving the understanding of materials and processes, faster and more sustainable production, and specifying the preconditions for 3D printing with fiber reinforcement in an industrial environment. Simultaneously, the team is working on structured testing of material properties, enabling SMEs to achieve reliable and repeatable series production. Within the NXTGEN Hightech Groeifonds program, work is also underway on topology optimization suitable for this new process.

The consortium consists of three knowledge institutions and seven SMEs: Saxion/TPAC, the University of Twente, and Delft University of Technology, along with Poly Products, CATO Composites, CEAD, CCM, Theuws Groep, KCCM, and Femto Engineering. Funding comes from RAAK-PRO (Regieorgaan SIA, part of the Netherlands Organisation for Scientific Research (NWO)).

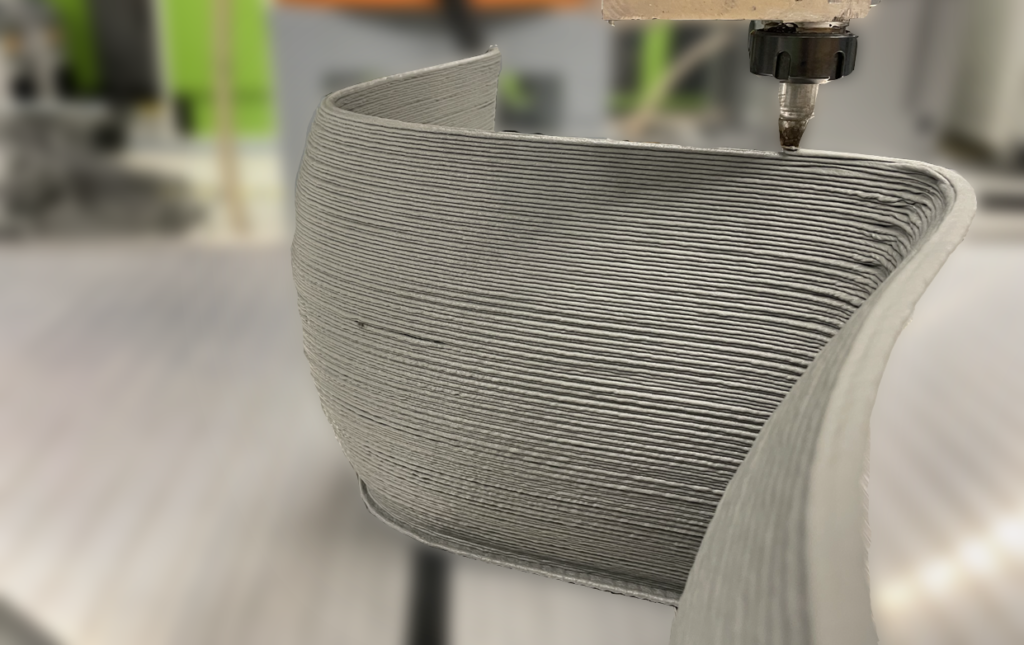

Prototype setup for 3D printing large, fiber-reinforced thermoplastic parts, a close-up.

Results

The initial results demonstrate cost-effective high-tech production. The prototype setup has already demonstrated integrated manufacturing of large, fiber-reinforced, 3D-printed thermoplastic parts with high mechanical performance and improved reproducibility. Investment costs are kept low by a clever design of the integrated print head for feeding the continuous f ibers. In short, technology that SMEs can implement immediately