rC/PPS printen

Research on 3D-printing of recycled composite waste material.

Summary

High-performance thermoplastic composites are widely used in aerospace and automotive applications because of their low weight and excellent mechanical properties. These materials are in principle recyclable, but in practice large volumes of valuable production waste are still underutilized.

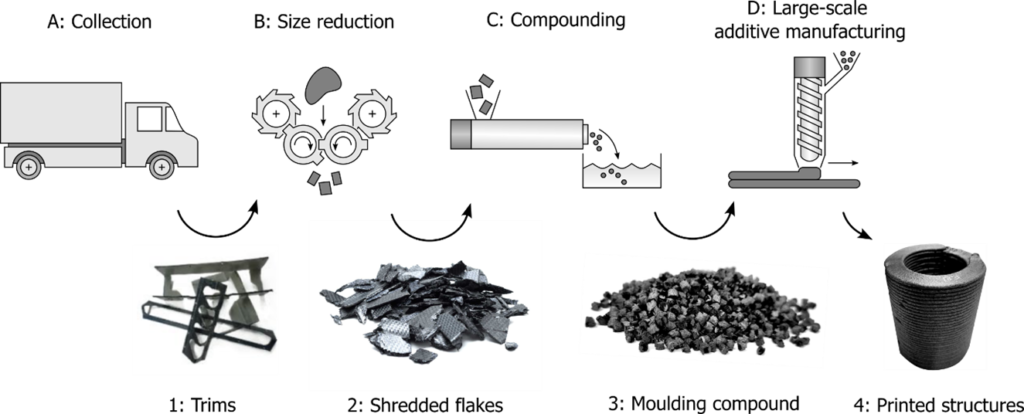

In this project, TPAC (Saxion), SPIRAL RTC and Kleizen Modelmakerij work together to develop a high-value recycling route for carbon fibre reinforced thermoplastic composites from the aerospace industry. Continuous-fibre waste materials are converted into short-fibre granulate and reused for 3D printing. The focus is on printing with recycled carbon fibre reinforced PPS (rC/PPS) for the production of industrial moulds for, for example, composite manufacturing. This application benefits from both the low thermal expansion of carbon fibre composites and the design freedom and cost efficiency of robotic large-scale additive manufacturing.

The project will focus on the following two questions :

- How the structural performance of printed rC/PPs parts can be reliably measured? With specific attention to interlayer bonding.

- What the relation is between the print parameters and these structural properties?

The research results are applied in the production and post-processing of a full demonstrator mould. The outcome of this project is a validated print process, a practical test methodology, and a demonstrator that shows the technical feasibility of using recycled aerospace composites for high-value industrial tooling.

Project partners

SPIRAL RTC

Modelmakerij Kleizen

Duration

1 year, Start in Sept 2025

Funding

Financed by KIEM High Tech, Regieorgaan SIA