Windkracht

Summary

Wind turbines are increasingly being used for the production of green electricity. With an average service life of 24 to 30 years, this means that the first generation of wind turbines is gradually reaching the end of its lifespan. This, combined with the growing number of wind turbines, results in an increasing availability of material for recycling. However, due to the use of thermosetting materials, this presents significant challenges. As a result, many rotor blades are currently landfilled or incinerated, which does not meet current sustainability requirements.

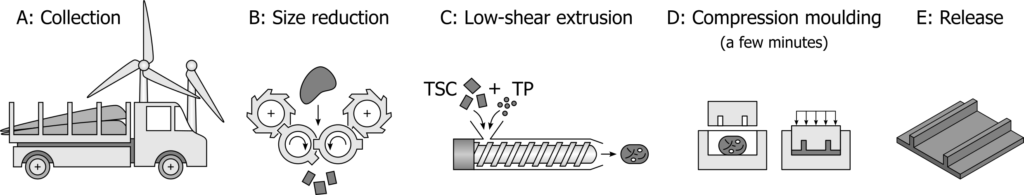

This research focuses on recycling rotor blades by combining them with consumer waste (thermoplastic recycling streams), with aims of retaining as much of the favorable mechanical properties as possible. Previous exploratory research has shown that it is possible to process rotor blade flakes with a thermoplastic matrix material, but many questions remain regarding the properties of the resulting material, the maximum filler content, and potential applications. In the search for potential applications, particular attention is given to applications within the wind industry. By reintroducing the material into the same sector, the circular economy of this material is promoted.

The current research focuses on preserving the fibers and their associated mechanical properties. This research is carried out using an in-house developed recycling process.

This consortium is a collaboration between Quattra-P, Technologie Centrum Noord Nederland, and TPAC. The objective of this research is to further investigate and develop the possibilities for recycling rotor blades.

Project partners

Quattra-P, Technologie Centrum Noord Nederland

Duration

1 year, Start in September 2025

Funding

Financed by KIEM High Tech