Background

The Saxion Academy of Life Science, Engineering and Design initiated the initiative to offer a revamped minor program to students starting in the 2025-2026 academic year. The focus was on hands-on education at and by the research groups and on developing contemporary, multidisciplinary programs that respond to the challenges of the future. TPAC enthusiastically spearheaded such a new minor program, partly built on successful elements from previous education, redesigned, and brought to life with TPAC’s expertise in advanced lightweight materials. The result: the minor in Sustainable Advanced Materials (SAM). Support from the Human Capital Agenda of the SolarNL ecosystem helped make this development possible.

The word ‘sustainable’ is everywhere these days. The minor uses the word ‘lightly’, but not light-mindedly. The world faces the major challenge of rapidly becoming more sustainable, which requires the development and application of innovative materials. Mass reduction through the use of lightweight composite materials with high mechanical performance plays a crucial role. Such materials enable energy savings in vehicles that are often still dependent on fossil fuels, and contribute to sustainable energy generation, for example, in wind turbines and solar panels.

But that is only one side of the story. Although lightweight materials often contribute to sustainability in their applications, they themselves are not always sustainable in their raw material extraction or reuse due to their complex composition. New solutions are needed to recycle and develop these materials at a higher quality and based on renewable resources. In the minor, students from six technical programs will spend six months working on both sides of this problem: how lightweight materials can contribute to sustainability, and how those same materials can become more sustainable themselves. In this way, they make a concrete contribution to the multidisciplinary challenges of the energy transition.

Kick-off pilot year

The first edition is now in full swing. In recent months, students have delved into the mechanical principles behind lightweight structures and learned to calculate them themselves. They also took a brand-new module on composite production, with a particular focus on the rapidly emerging thermoplastic variants.

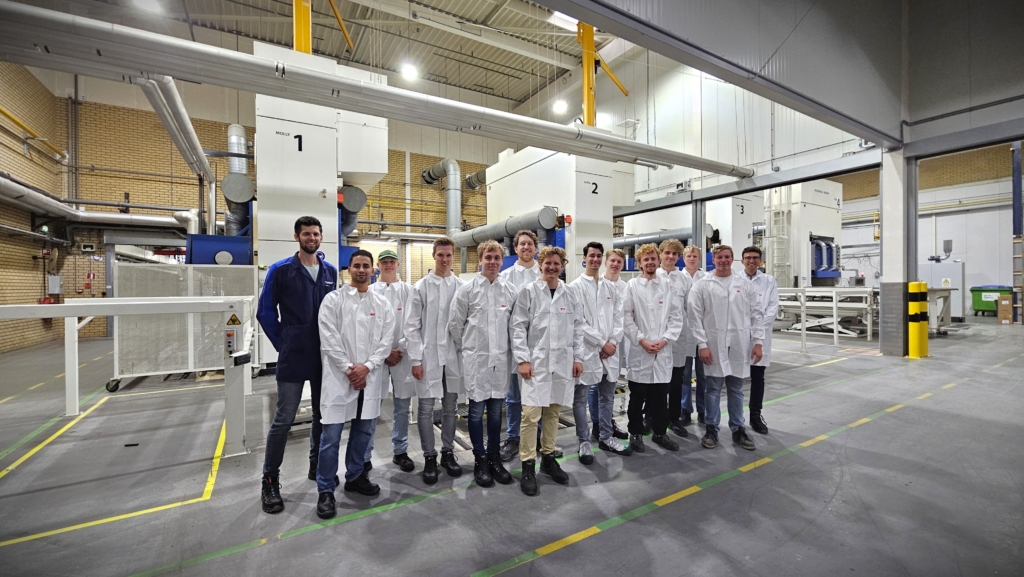

One of the highlights of the minor is the close collaboration with the business community. Students participated in a series of excursions and guest lectures from companies and research institutes in the eastern Netherlands, such as Toray Advanced Composites, TPRC, AniForm Engineering, and Spiral Recycled Thermoplastic Composites. At Toray in Nijverdal, students were given an impressive tour of the production f loor, where they saw the entire thermoplastic composite manufacturing process: from weaving carbon fibers to pressing meters-long sheets. During the guest lectures, they learned how these sheets are processed into structural products and how they can be recycled. Much of the theory was then immediately put into practice in the TPAC laboratory during a series of practical sessions.

Finally, in the new Experimental Methods module, students carried out their own measurement assignment based on current questions from the business community, often with a sustainability focus. Think of research into the electrical conductivity of the latest generation of recycled composites, or the adhesion between print layers in large-scale 3D printing with recycled thermoplastic granulate. These projects address current themes and require engineers who are not afraid of a challenge.

Remaining period

In the second half of the minor, students choose a more in-depth track. The engineering track focuses on students with a mechanical background: they delve into calculation methods for structures and build and test composite bridges themselves, including using 3D printing. Students with a background in chemistry follow the life-science track, in which they research the life cycle and environmental impact of advanced materials; they also participate in TPAC’s circular projects on composite recycling during a part-time internship. In this way, both groups put their knowledge into practice from their own specializations.