Processing of rTPC

Researching the development of an industrial process to recycle ThermoPlastic Composite (TPC) materials on an industrial scale.

Summary

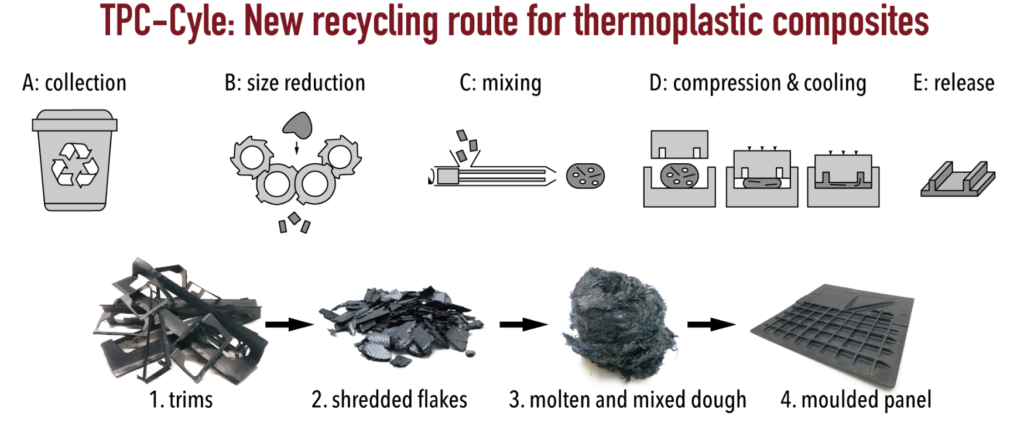

The demand from industry for research into the possibilities regarding the recycling of thermoplastic composite materials has increased in recent years. In the RAAK PRO project ‘TPC-Cycle – Sustainable Reuse of Thermoplastic Composite Materials’, two PhD students developed a recycling process. This process can be used to recycle post-production waste from high-end industries, such as Aerospace. This RAAK PRO project led to a follow-up research with one of the partners, GKN Aerospace. Within this TFF project, ‘rTPC Demonstrator’, material properties were further researched, and the possible geometry complexity was extended.

Within these projects it became clear that the TRL levels of the recycling process are not yet acceptable for an industrial environment. During the TFF project rTPC indusrialised, the possibilities for the industrialization of the recycling process were investigated. In addition, the first steps were taken towards broadening the material types to be processed (both fibre and matrix) .

Among others, GKN Aerospace, Collins Aerospace (DTC) and Toray Advanced Composites subsequently came with the request to further investigate this recycling process. Also for other polymers such as PEKK and LMPAEK and, to develop a system suited for an industrial environment. Additional research is required, because currently a lab setup is being used. This means that the machine is not directly deployable within the industry for several reasons. Mainly because it’s a lab scale machine, that is partly manually operated, and it is a machine that works with one batch per cycle. Further research could result in a industrial variant of this setup, a redesign of the current machine that industry could use. In addition, the reliability could be increased, by automating the process and removing manual work. Finally, the batch process could be converted into a continuous process, this would improve the cycle times and better match with industrial demands.

The aim of this project is to further industrialise the developed recycling process and make it available to the market. This results in the following research question:

What is needed to industrialise the developed low-shear mixing process, see figure above step C, and make it suitable for a wide range of materials types and follow-up processes?

Furthermore additional research will be done on the following area’s:

- Can this technology be further developed to also process other high-quality materials, such as C/PEKK?

- Can this technology be further developed to process chopped C/PPS UD tapes?

- In addition to direct pressing of products, can this technology be used to produce semi-finished products in sheet form?

- What are the material properties of the proposed further developments? And would would be the effect of any contamination to the waste stream (glass scrim, LSP)?

Project partners

GKN Aerospace, Collins Aerospace and Toray Advanced Composites

Duration

2 years, Start in September 2022

Funding

Partly financed by Tech For Future, Centre of Expertise HTSM Oost.