TPC Cycle

Summary

Continuous fiber reinforced thermoplastic composites (TPC) are gaining interest in aerospace and more recently also sporting goods, automotive and industrial sectors. The growing demand results in increasing post industrial waste. During the production process up to 1/3 of the material is waste resulting in circa 1000 ton of high-end TPC till 2024 in the Netherlands only. Lately, also more low-cost high-volume materials are used and resulting in more production waste. Since there is no adequate recycling solution for TPC materials, the waste is often disposed. The result is a considerable economical loss. For high-end TPC roughly 100M euro is estimated. Beside the economic motivation, legislation and more environmental awareness is making recycling more interesting. In contrary to their thermosetting counterparts TPC can be reprocessed by reheating and is therefore considered to be recyclable.

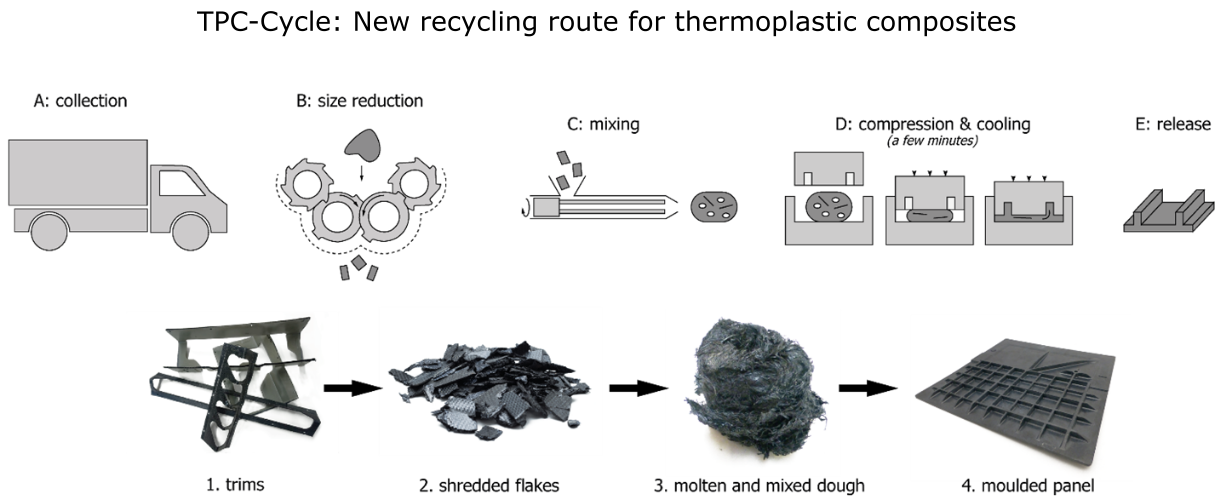

The TPC-Cycle project aims at developing a recycling route for TPC materials. The research focuses on the optimum process and process settings to cost-effectively reprocess TPC waste to obtain the highest performance possible. The project covers the total value chain, from design and size reduction to the forming of parts. To understand the influence on the mechanical performance of the material all processing steps are included in the project. The performance is measured by material performance regarding the stiffness, strength and impact toughness. These properties are a result of, among others, fiber length and degree of mixing. Costs are both economic and environmental. Including the financial cost of the recycling to the value of the solution and the feasibility and risks involved and is validated by producing a demonstrator.

Project partners

TPRC, Toray Advanced Composites (Toray Group), Nido Recycling Techniek, DTC, Cato Composite Innovations, GKN Fokker Aerostructures, Saxion Lectoraat Industrial Design

Duration

4 years, Start in September 2015

Funding

RAAK-PRO subsidy, financed by Regieorgaan SIA, part of the Netherlands Organization for Scientific Research (NWO)

More information

A short summary can be found here. For more information about this project please click here for a leaflet.

A press release regarding the rotocraft access panel from recycled carbon PPS can be found here, including a leaflet.

For information about the safety shoe nose from recycled thermoplastic composites please click here for a leaflet.

TPC Cycle project in the NEWS

- Rotocraft access panel from recycled carbon PPS – World’s first flying fully recycled thermoplastic composite application in aerospace

Composite Solutions & Technopolymers, Nr. 2 2020 - Wereldprimeur voor TPAC van Saxion met gerecycled vliegtuigonderdeel

Twente.com website, News post: 04/09/2020 - Recycled thermoplastic composite rotocraft access panel takes flight

Composites world website, News post: 27/07/2020 - HOW IT’S MADE – A rotocraft access panel made from recycled carbon PPS

JEC website, News post: 01/07/2020 - Gebruikte vliegtuigonderdelen recyclen

Kunststof & rubber nieuws website, News post: 29/06/2020 - Wereldprimeur: eerste vlucht met gerecycled composiet

OostNL website, News post: 25/06/2020 - Wereldprimeur: Saxion brengt het ‘groene’ vliegen dichterbij

De gelderlander website, News post: 23/06/2020 - Wereldprimeur: Saxion brengt het ‘groene’ vliegen dichterbij

AD website, News post: 23/06/2020 - Wereldprimeur: Saxion brengt het ‘groene’ vliegen dichterbij

De stentor website, News post: 23/06/2020 - Nederlandse methode om koolstofvezels te recyclen blijkt succesvol

Recycling magazine website, News post: 23/06/2020 - Eerste vliegtuigonderdeel van gerecycled composiet ter wereld succesvol getest

BNR niewsradio website, News post: 23/06/2020 - Wereldprimeur Saxion brengt het groene vliegen dichterbij

Tubantia website, News post: 23/06/2020 - Primeur Saxion Enschede, reclclebaar restaafval vliegtuig

Tubantia website, News post: 23/06/2020 - Wereldprimeur rotocraft vliegt met door Saxion ontworpen toegangsluik van gerecycled materiaal

Saxion website, News post: 22/06/2020 - Vliegtuig met gerecyclede materialen, is dat de toekomst?

Duurzaam bedrijfsleven website, News post: 22/06/2020 - Nederlandse methode om koolstofvezels te recyclen blijkt succesvol

Luchtvaart nieuws website, News post: 20/06/2020 - Saxion Enschede zet flinke stap op weg naar duurzaam vliegen

Tubantia website, News post: 18/06/2020 - Productie duurzaam vliegtuig stap dichterbij

Transport online website, News post: 18/06/2020 - Gerecycleerd koolstofvezelcomposiet doorstaat vliegtest

Engineers online website, News post: 18/06/2020 - Productie duurzaam vliegtuig stap dichterbij

Duurzaam ondernemen website, News post: 18/06/2020 - Rotocraft access panel from recycled carbon PPS

TPAC website, News post: 12/06/2020 - GKN Aerospace’s thermoplastic components flight tested on bell V-280 valor

GKN Aerospace website, News post: 04/06/2020 - Thermoplastic components successfully flight tested on Bell V-280 Valor

Composites World website, News post: 04/06/2020 - GKN Aerospace’s thermoplastic components flight tested on Bell V-280 Valor

JEC Composites website, News post: 04/06/2020 - CAMX unsurpassed innovation award

TPAC website, News post: 16/09/2019 - The state of recycled carbon fiber

Composites World website, News post: 04/09/2019 - GKN Aerospace thermoplastic composites featured on Bell V-280

Composites World website, News post: 20/06/2019 - Safety shoe nose from recycled thermoplastic composites

TPAC website, News post: 02/11/2018 - Saxion-student ontwerpt neus veiligheidsschoen van afvalcomposiet

KUNSTSTOF & RUBBER website, News post: 01/11/2018 - TPAC and TPRC develop thermoplastic composites recycling process

Composites World website, News post: 19/10/2018 - New recycling route for thermoplastic composites

TPAC website, News post: 17/10/2018 - Nederlandse onderzoekers geven ‘wondermateriaal’ koolstofvezelcomposiet tweede leven

SCIENTIAS article, 09/2017