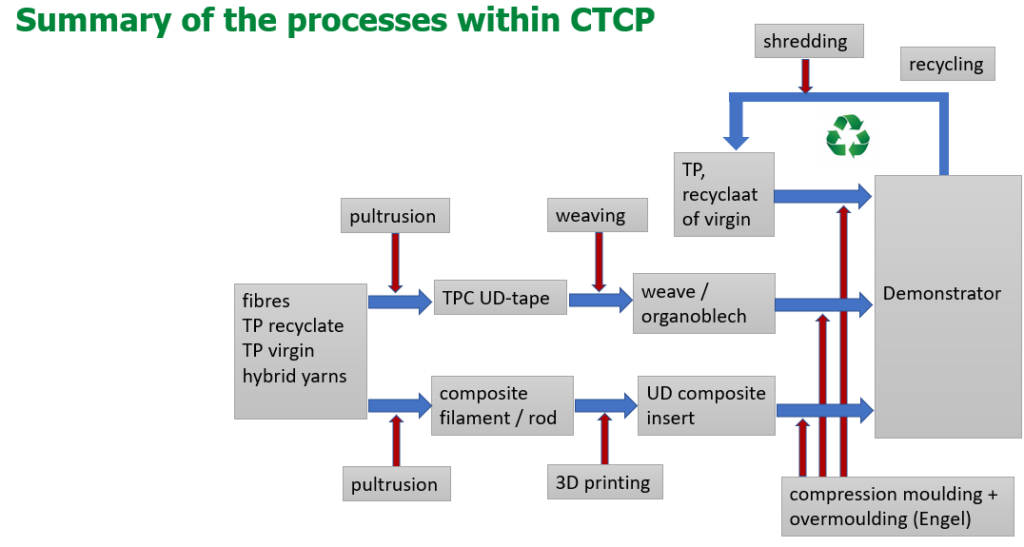

In the project “CTCP – Circular Thermoplastic Composite Production”, 6 SMEs and 2 Universities of Applied Sciences carried out R&D on the circularity of thermoplastic composites.

The project, financed by Regieorgaan SIA, part of the Netherlands Organization for Scientific Research (NWO) through a RAAK-MKB subsidy, was successfully completed earlier this year.

The following goals were achieved:

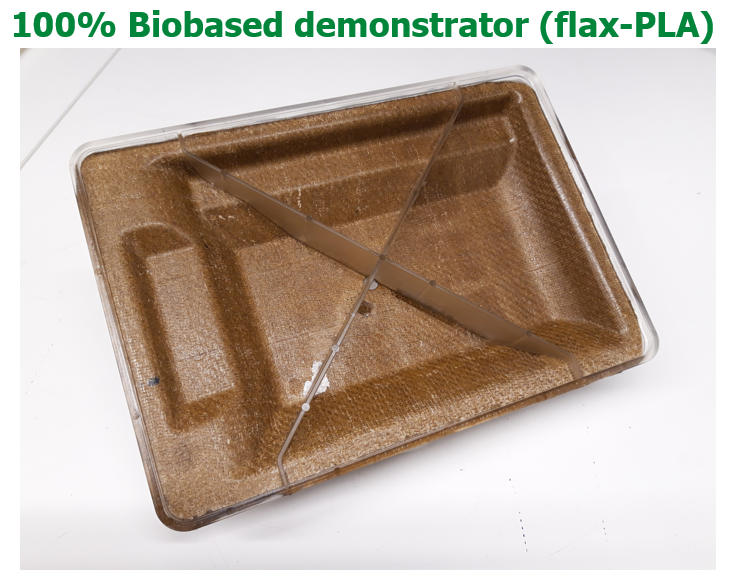

- New material combinations were developed and transformed into UD-tape prepregs. Among these materials: Single Polymer Composites (fibre and matrix are made from the same polymer) and Biobased Composites (natural fibres and biobased polymers

- Laminates were produced and mechanical properties were determined

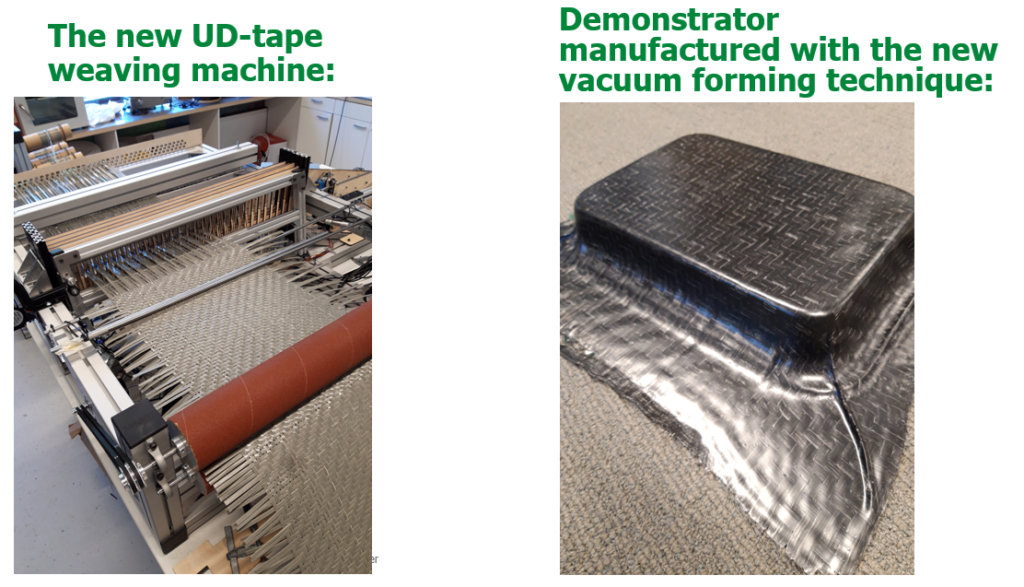

- A new weaving machine was designed and built especially for the weaving of UD-tapes

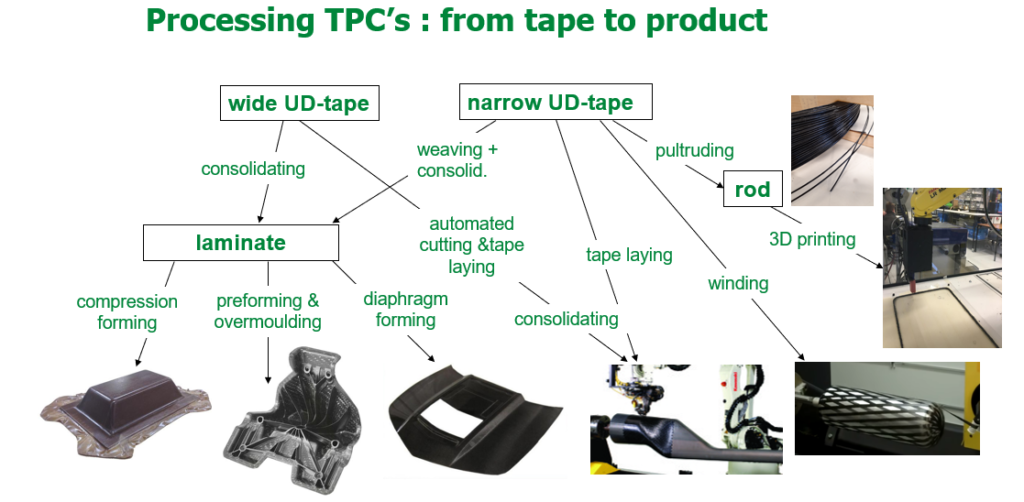

- Processing technologies with the new TPC prepregs were investigated,

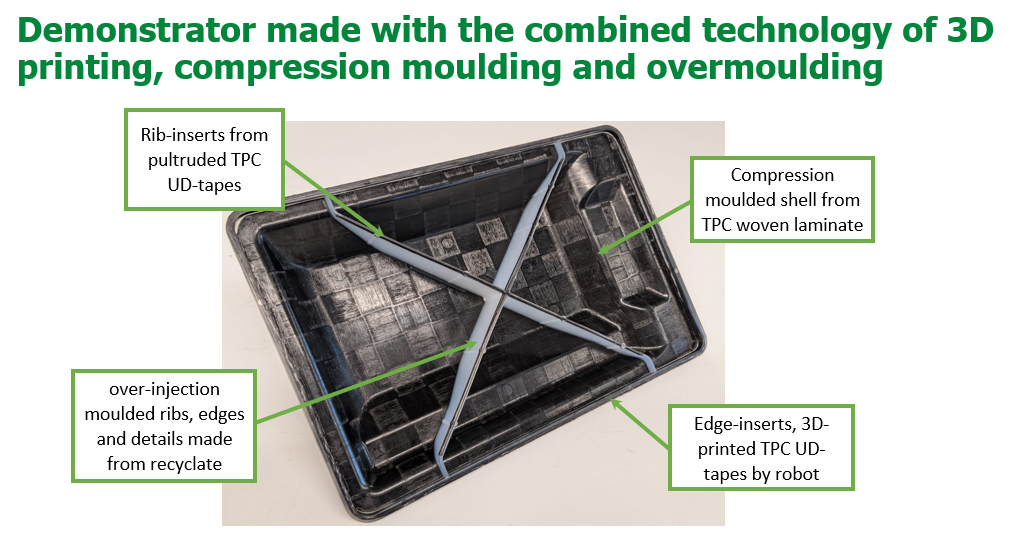

such as: vacuüm forming, pultrusion, compression moulding, over-moulding and 3D printing

- Demonstrators were manufactured that served the interests of the SME’s