rTPC Demonstrators

Research into the use of recycled Thermoplastic composite materials in practice

Summary

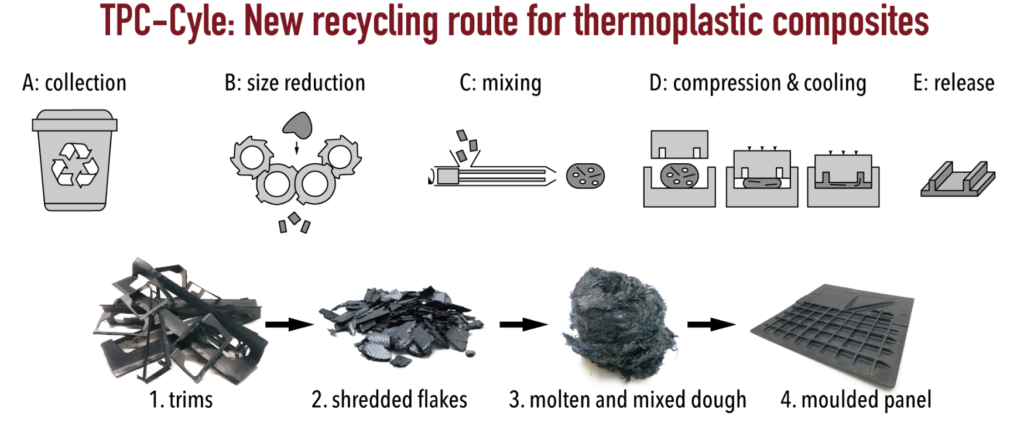

In the RAAK PRO project ‘TPC-Cycle – Sustainable Reuse of Thermoplastic Composite materials’, two PhD students investigated processes to recycle thermoplastic composites. In particular, post-production materials from the high-end industry (aerospace) proved to be reprocessable into new product forms, while retaining a large amount of the mechanical properties and are of interest from a economic and environmental perspective. By making parts of the same aircraft, the material supply and demand could be linked. Participating project partners are very enthusiastic, and are urging follow-up research. GKN Aerospcae has asked to further develop this technology, by means of:

- Conducting further research into the validation of product requirements for a future industrial product;

- Integrating production steps, such as applying (conductive) foil as an integrated lightning strike top layer in this prototype (including testing);

- Investigating the damage sensitivity of the proto-production process through impact testing;

- Extend complexity of the geometry in a more complex prototype, in this case through the 3D shape of fairings;

- Investigate and produce two prototypes for further investigation and use as recycling demonstrators within and outside the aerospace industry.

The aim of this project is to develop two prototype aircraft parts from recycled thermoplastic composite (rTPC), including increasing the generic knowledge:

A. Generic flat product/panel for material characterisation. The aim is:

- Research on integration of (electrically conductive) sheets for lightning impact protection + testing their effectiveness in this prototype

- Characterisation and validation by impact testing (establishing damage sensitivity)

- Additional material characterisation by coupon (tensile) testing in critical usage conditions

B. Development of a (flying) prototype part (fairing, consisting of two parts of approx. 10×25 cm) from recycled TPC.

Both goals achieve more practical design knowledge for this technology, and provide more detailed answers to critical feasibility issues for a serial application in the aerospace and increase the knowledge of the application area (freedom of form, operating environment).

Project partners

GKN Aerospace

Duration

2 years, Start in September 2019

Funding

Partly financed by Tech For Future, Centre of Expertise HTSM Oost.

For more information about this project, please click here.