Meet our interns!

At TPAC, we are committed to providing an inspiring and hands-on learning environment for students. We welcome MBO, HBO, and WO students for internships and graduation projects, giving them the opportunity to work on real-world challenges. Currently, five students are working on a variety of projects.

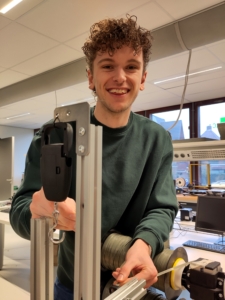

Jochem Vlutters is a graduate student from ROC van Twente who is working on our in-house developed tape weaving machine.

“The goal is to make the machine more reliable, and robust. Main improvements include better drive systems, an improved electrical setup and enhanced safety features. By the end of the project, the machine should be fully operational.”

Herjo van Triest is a fourth-year Mechanical Engineering student at the University of Applied Sciences who just started his internship at TPAC. During this internship, he will design and manufacture a tension monitoring system for thermoplastic tape winding.

Herjo van Triest is a fourth-year Mechanical Engineering student at the University of Applied Sciences who just started his internship at TPAC. During this internship, he will design and manufacture a tension monitoring system for thermoplastic tape winding.

“The goal is to precisely control the tape tension during the winding process, making for a better understanding of its effect on layer adhesion. This insight will contribute to improving the quality and reliability of wound composite products.”

Laura van Essen, a second-year master’s student in Mechanical Engineering at the University of Twente, is also interning at TPAC.

“My research focuses on identifying and validating a method to experimentally quantify shrinkage in 3D-printed products with fiber reinforcement. During printing, cooling causes thermal shrinkage, leading to deformation and internal stresses. A novel 3D-printing technique is developed at TPAC to mitigate these problems, and the method I will develop will allow us to quantify the effectiveness of these techniques.”

Furthermore, Bas Dijkstra, a second-year MBO Mechatronics student, is completing an internship at TPAC.

Furthermore, Bas Dijkstra, a second-year MBO Mechatronics student, is completing an internship at TPAC.

“I work on various small assignments to improve machines. The goal is to ensure that the machines can operate independently without requiring constant supervision.”

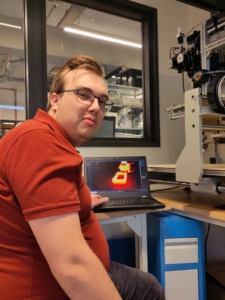

Finally, Jasper Dekker is working on his internship assignment for his fourth year of Mechatronics at Saxion University of Applied Sciences. He is developing a prototype to monitor temperature during 3D printing.

“A major challenge in 3D printing is inconsistent layer adhesion, which affects print quality. To address this, my project aims to improve adhesion by actively adjusting the printing process based on real-time temperature data, ultimately enhancing the overall print results.”