The TPAC research group studies new manufacturing methods using thermoplastic composite materials, often in the form of prepreg tapes (fibres pre-impregnated with a polymer). These tapes are bonded by melting their surfaces and pressing them together. The quality of consolidation (combining layers into a solid laminate) depends on factors like tape quality, polymer viscosity, cooling rate, and applied pressure. Perfect consolidation is not always required; for example, minor voids may not affect the performance of a filament-wound pressure vessel.

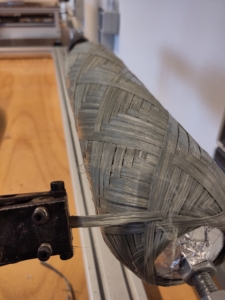

TPAC uses automated equipment for tape processing, such as automated tape laying (ATL) in filament winding. They are developing a tape winding line using a 5-axis robot to produce large cylindrical tanks. Various heating systems, like Hot Gas Torches, Laser Heaters, or Pulsed Light Heaters, can be used to heat the tape before winding. Factors such as winding speed, heating power, and cooling impact consolidation quality.

The key research questions are:

- Which heating and deposition system is best for our tape winding process, considering cost, reliability, and quality?

- Can the heating and cooling process be modelled theoretically and parametrically?

Other information

We are seeking a motivated student enrolled in a MBO or HBO program in mechanical engineering or mechatronics for a 6-month internship. As an intern at TPAC, you will have a desk in our office and receive a gross trainee compensation of €475 per month.

Interested? Contact us!

Join us to enhance your skills and grow professionally in a dynamic and supportive environment. Please send an email addressed to:

Rik Brouwer; w.d.brouwer@saxion.nl; +31(0)6-12315655

For the pdf of the intern assignments ‘Modelling of tape winding’, click here.