Ilse ten Bruggencate wins two awards with master thesis

Author: Anne Hurenkamp Photography: Thomas Busschers (Dienst Marketing Communicatie) Date: 9 December 2025 Source: Saxion news Ilse ten Bruggencate wins two awards for her master research Anyone who has ever looked out of an airplane window will recognize them: the moving flaps at the end of the wing. They are closely connected to the research of lecturer [...]

Sustainable Advanced Materials minor

Background The Saxion Academy of Life Science, Engineering and Design initiated the initiative to offer a revamped minor program to students starting in the 2025-2026 academic year. The focus was on hands-on education at and by the research groups and on developing contemporary, multidisciplinary programs that respond to the challenges of the future. TPAC enthusiastically spearheaded such a [...]

New Generation Stiffened Thermoplastic Composite Product

The project focuses on the development of a new generation of stiffened thermoplastic composite products that are lighter, more durable, and cost-efficient to produce. The use of thermoplastic composites (reprocessable and meltable) overcomes the limitations of thermosets. This creates the prospect of circular and scalable production for sectors such as air and road transport, energy, and consumer goods. [...]

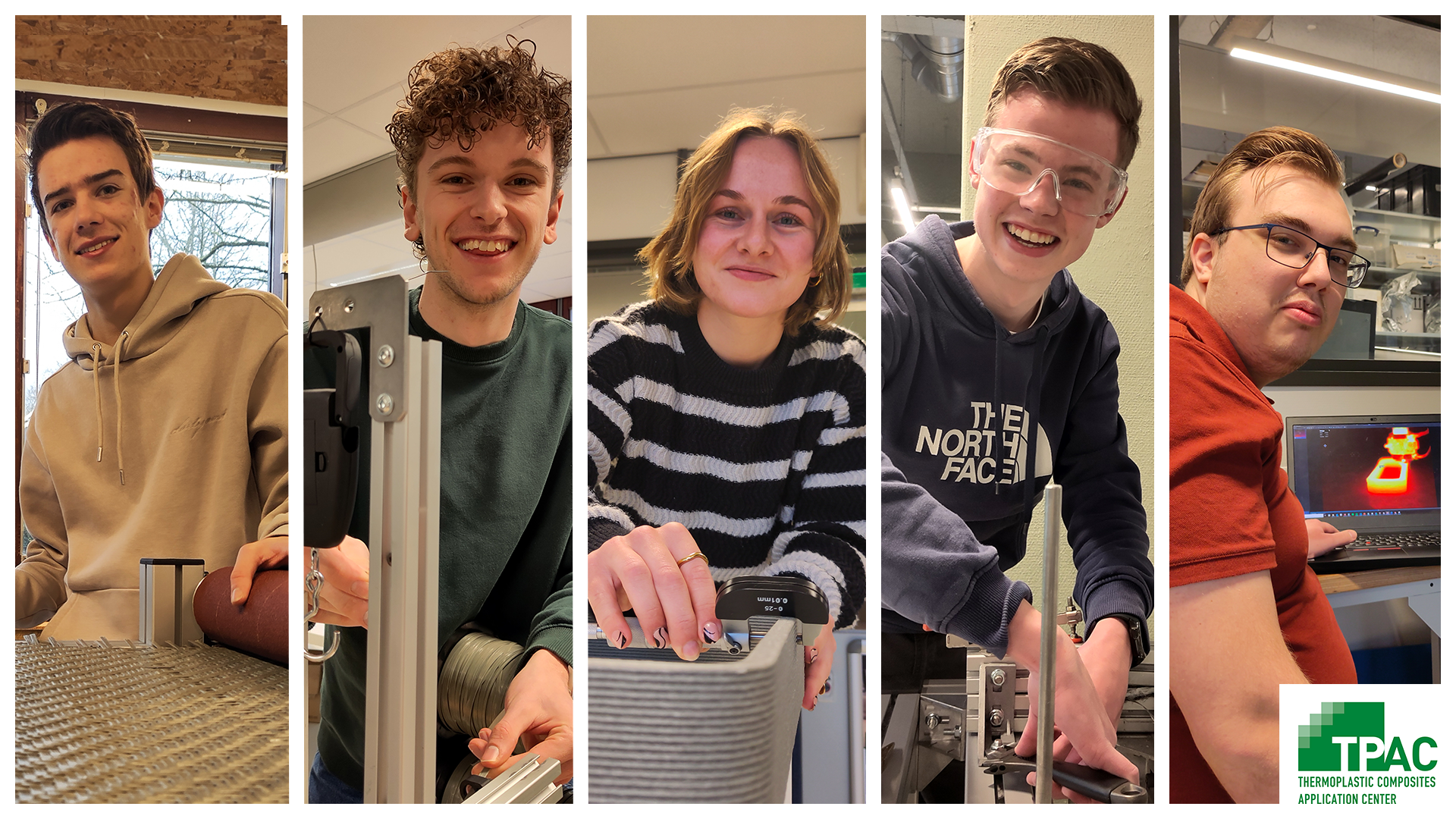

Students at TPAC

Meet our interns! At TPAC, we are committed to providing an inspiring and hands-on learning environment for students. We welcome MBO, HBO, and WO students for internships and graduation projects, giving them the opportunity to work on real-world challenges. Currently, five students are working on a variety of projects. Jochem Vlutters is a graduate student from ROC van [...]

Happy Holidays!

Thank you for your collaboration in 2024. We wish you a wonderful Holiday Season and a happy and peaceful New Year. Looking forward to continue working with you in 2025!! On behalf of the entire TPAC-team, Ferrie van Hattum

Students design NS luggage racks using technology developed by TPAC

A multidisciplinary group of Saxion students was given the task last semester to investigate market-driven opportunities for the application of thermoplastic technologies developed by TPAC. TPAC has been working for over 10 years on developing cost-efficient production technologies for thermoplastic composite products. We are noticing that more and more companies are eager to transition to thermoplastic composite materials [...]

Fibre reinforced prostheses pass the test

In the Twente region, an ecosystem focused on medical 3D printing has developed over the past few years. Researchers from Saxion University of Applied Sciences collaborate with the Medisch Spectrum Twente, Ziekenhuisgroep Twente, Roessingh Rehabilitation Center, OCON, and various (commercial) partners. Within this ecosystem, 3D printing is used to create preoperative models, cutting guides, and simple medical devices, [...]

Kick-off: Next Thermoplastic Composite Manufacturing Solutions

In April the kick-off took place of the Lighthouse 1 project as part of the Interreg “Manufacturing Next Materials”. Here, TPAC and CATO are working together on the production of thermoplastic composite applications. This collaboration is set up to specifically help SMEs with the conversion and professionalization of the manufacturability of these applications. This not only offers benefits [...]

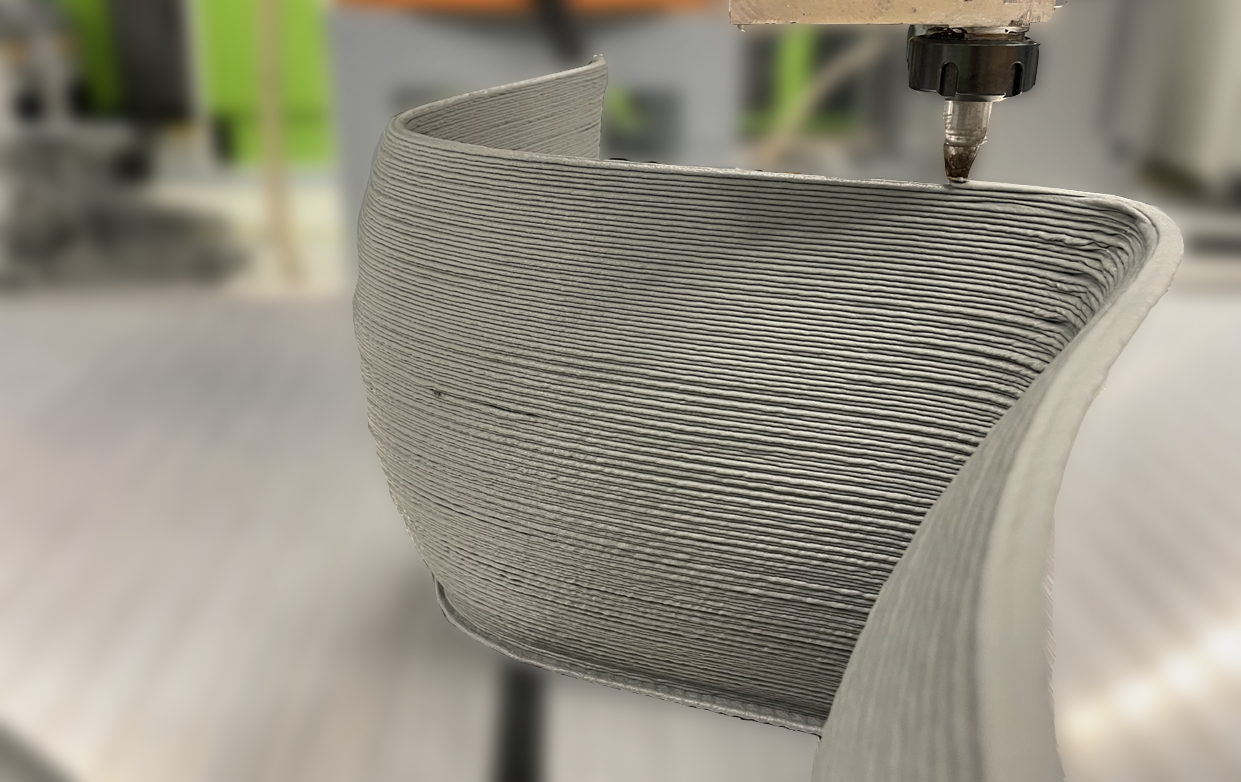

3D wood printing

The project is investigating the possibility of using lignin and cellulose for 3D printing. With only these two materials it turned out not to be possible to print properly. Therefore, the bio-based polymer PLA (from corn starch) was used as a binder. The PLA is essential to get enough material into the flow for controlled extrusion. First [...]

Students at TPAC

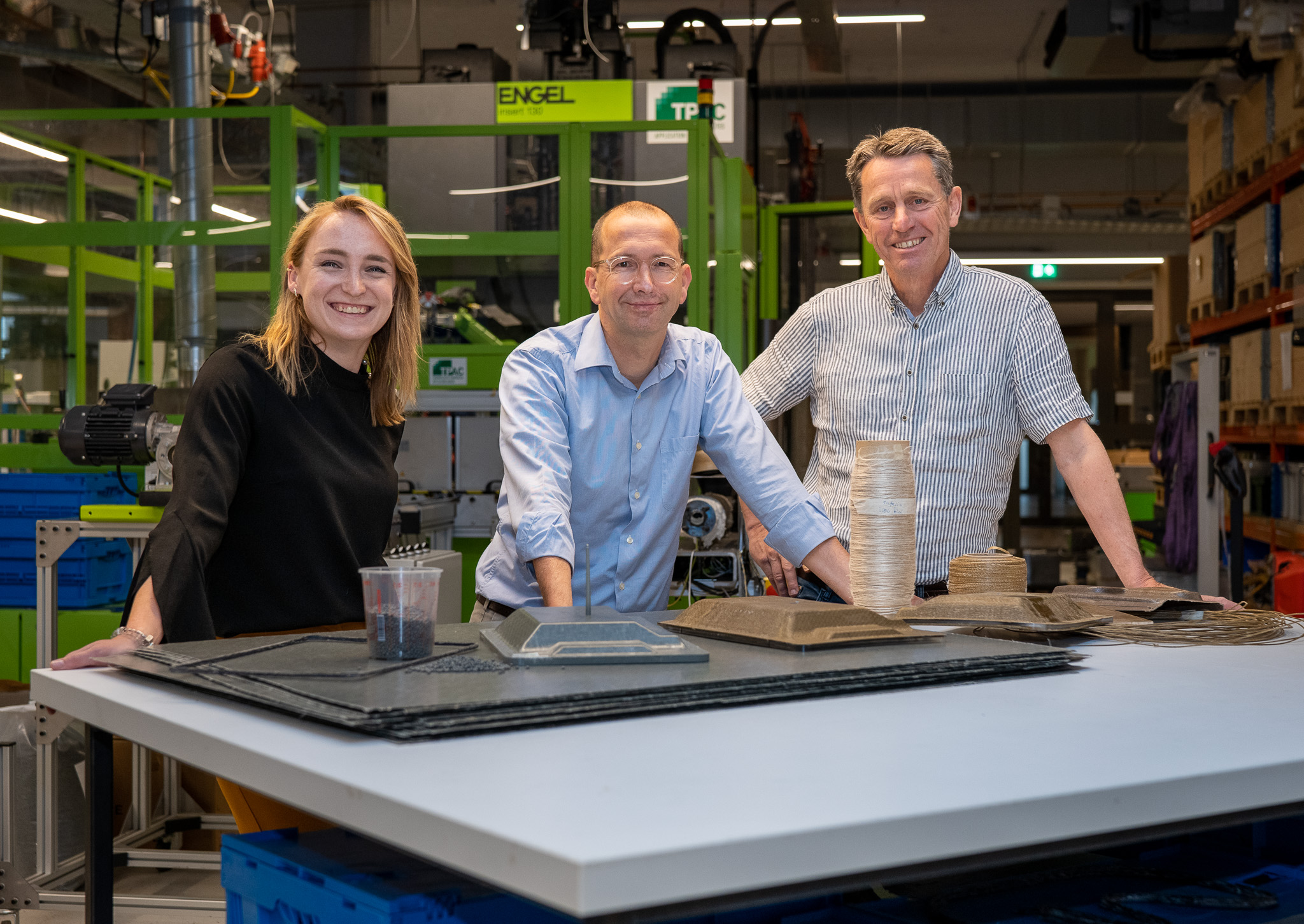

In 2024 a number of students have started their internship or graduation assignment at TPAC. Currently we have interns varying from Mechatronics, Mechanical Engineer to Industrial Design, either from Saxion, ROC Twente or the University of Twente. From left to right: Stijn Baars, Manu Warnet, Tim van Berloo, Mika van der Schaaf and Daan van der Zalm. [...]

TPAC is celebrating its 10th anniversary

Over the past period, we have been working hard on expanding our laboratory, resulting in a significant increase in lab facilities and the installation of multiple industry-sized machines. This development allows TPAC to better serve its role as an R&D partner for businesses and its role in education! Additionally, TPAC is celebrating its 10th (!!) anniversary this year. [...]

Expansion TPAC laboratory

In recent weeks, the expansion of TPAC's laboratory has been in full swing. We've relocated machinery from our original laboratory to create space for new, industry-sized equipment that is already eagerly waiting to be employed! The lab's floor has been reinforced to accommodate a delivery: of a KUKA robotic arm with an impressive 4.8m range. Paired with [...]

Finalization project: Post-use Plastic Foil solutions

This project contributes to the objectives of the European Green Deal. The plastics recycling industry still has a long way to go to become fully circular. Many companies share problems in different variations. Used foils and thin-walled plastics (Post-use Plastic Foil or PPF) are a substantial obstacle to the circular economy, as they represent a large share of [...]

TPAC laboratory expansion (update)

Our new laboratory space (290 square meter) is almost finished. This will allow TPAC to move its labscale- and test-equipment to the new lab space, reserving the current lab space for industrial equipment, allowing for trials closer to industrial reality. The new laboratory space will be operational in September. Furthermore, a Kuka robot with a CEAD extruder [...]

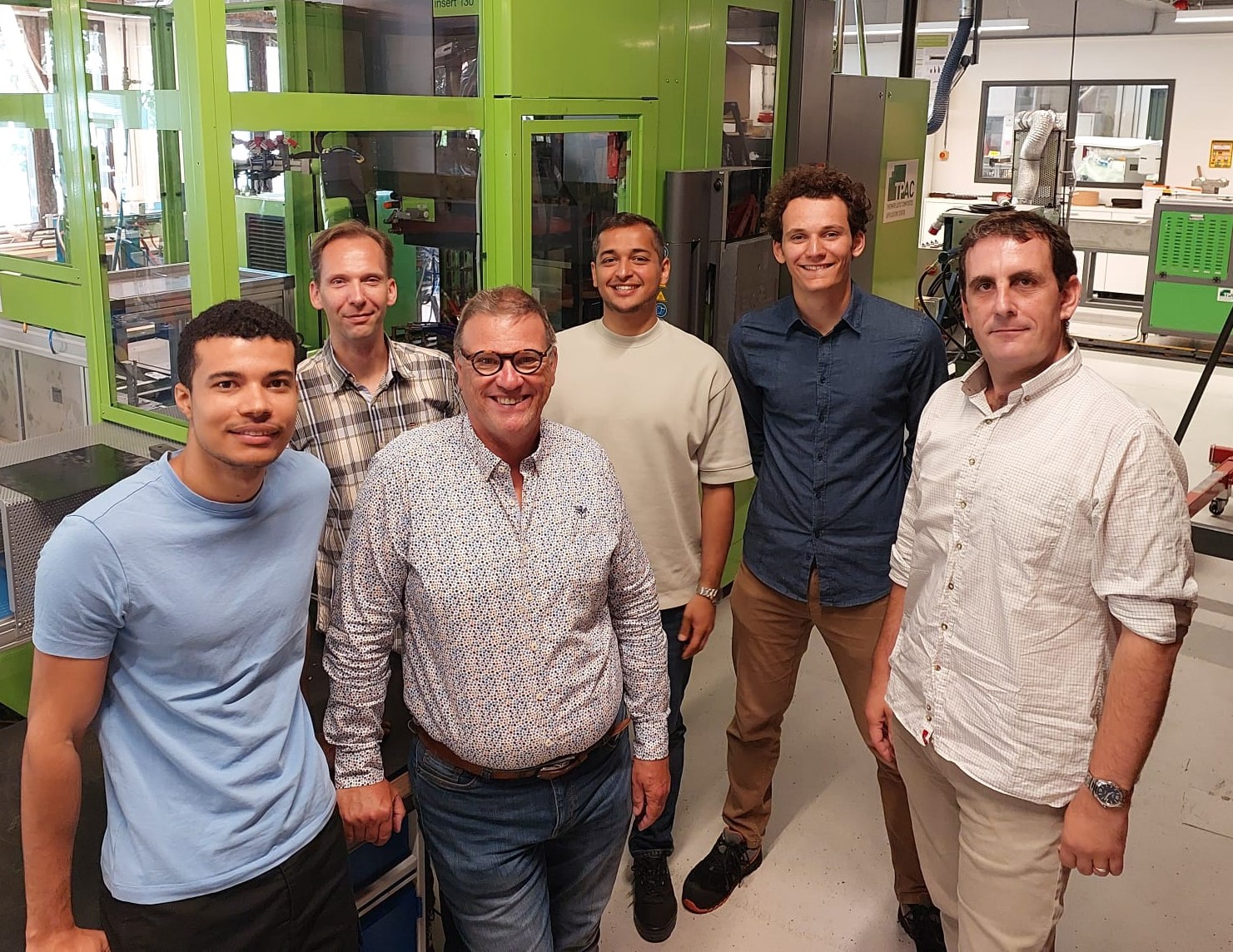

New employees at TPAC

The last period, a large group of new employees has joined our TPAC team. We would like to use this moment to introduce all of them. From left to right: Wallison da Silva Bezerra, Martijn Jannink, Peter Verschut, Ibrahim Can Kaymaz, Allard Braakhuis and Özgür Seydibeyoğlu Wallison da Silva Bezerra Graduated in Mechanical Engineering from the [...]

The sustainable promise of lightweight composites

Auteur: Jos Eertink Photography: Thomas Busschers Date: 4 July 2022 Source: Saxion News At Saxion’s Lightweight Structures research group (better known as TPAC- ThermoPlastic composites Application Center), flax fibres form the basis for sustainable sheet material, and composite tapes made of recycled plastic [...]

First year’s Mechanical Engineering students at TPAC

Today first year's Mechanical Engineering students from Hogeschool Saxion came to visit TPAC for a short introduction of the research group and a tour of the lab facilities. In the following weeks they will be involved in (injection moulding) practical training.

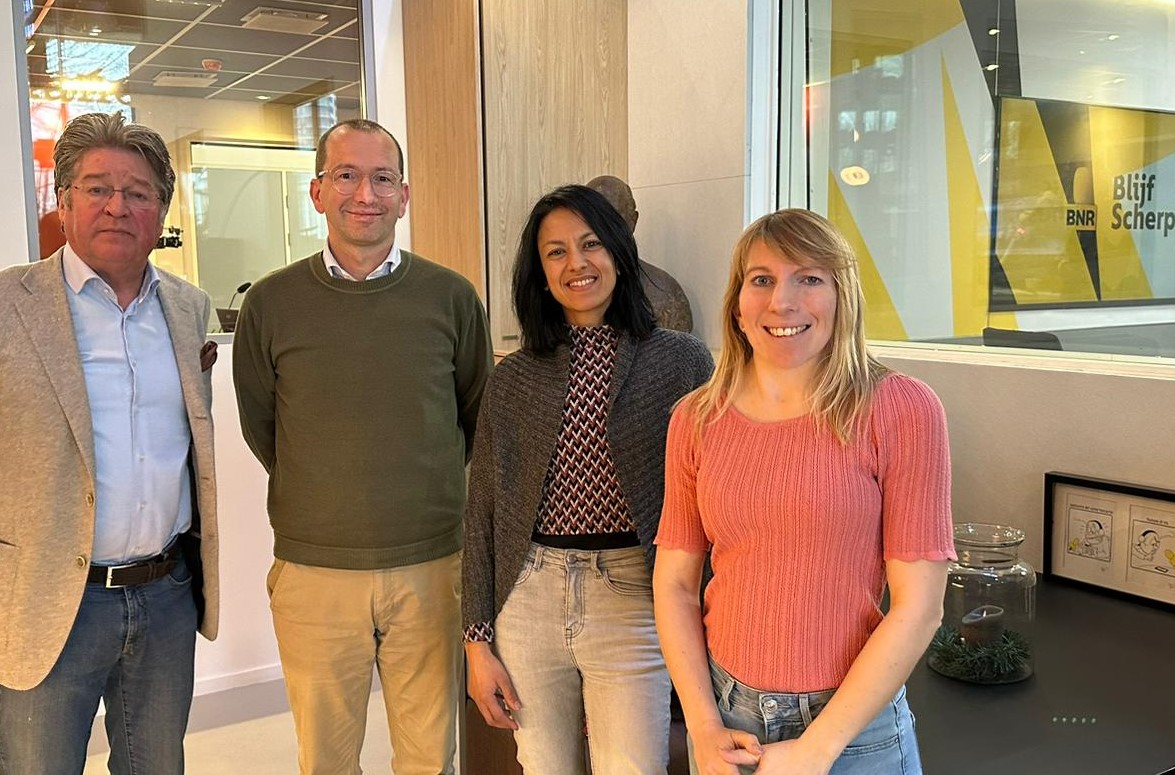

Ferrie van Hattum on BNR Eyeopeners

On BNR Eyeopeners, Ferrie van Hattum talks about composites and how they are more and more used in different industries. To listen to the complete podcast, click here.

TPAC presents

On 17th November, our colleague Ferrie van Hattum presented at the AZL GmbH Hybrid Thermoplastic Composites Workgroup Meeting in Aachen, Germany, on TPAC’s progress on recycling of thermoplastic composites and biobased thermoplastic composites. In the meetings, professionals from research and industry meet, present and discuss their latest developments. Earlier, on 7th October, TPAC was also invited to [...]

Fibre reinforced extrusion

In the Post-Use Plastic Foil solutions project we develop low-cost techniques to reprocess thin-walled waste plastics from local waste sources into products. Heavily polluted plastics, such as post-consumer packaging, often have lower mechanical properties, as separating and cleaning of the various plastics involved is difficult and expensive. One option is to reinforce the material with glass fibres: [...]

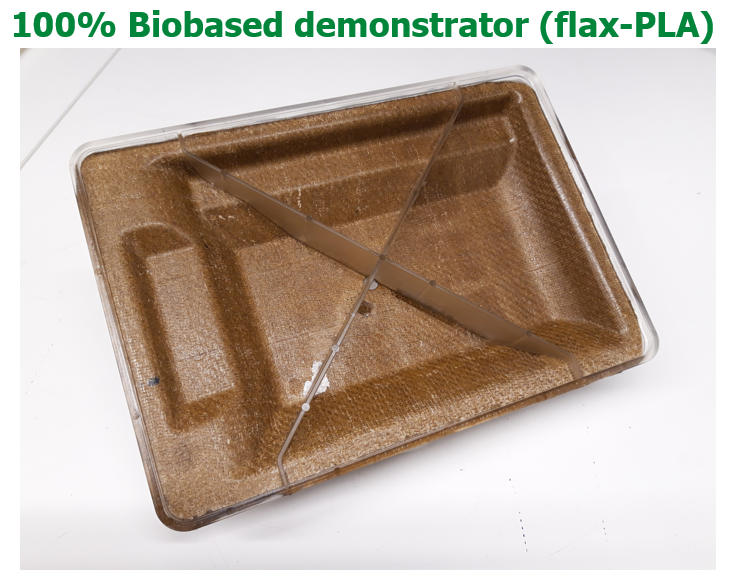

CTCP – Circular Thermoplastic Composite Production

In the project "CTCP - Circular Thermoplastic Composite Production", 6 SMEs and 2 Universities of Applied Sciences carried out R&D on the circularity of thermoplastic composites. The project, financed by Regieorgaan SIA, part of the Netherlands Organization for Scientific Research (NWO) through a RAAK-MKB subsidy, was successfully completed earlier this year. The following goals were achieved: New material [...]

TPAC laboratory expansion

TPAC is growing and, therefore, our laboratory space will be expanded with an additional 290 square meters of floor space. This will allow TPAC to move its labscale- and test-equipment to the new lab space, reserving the current lab space for industrial equipment, allowing for trials closer to industrial reality. This expansion will also allow the industrial lab [...]

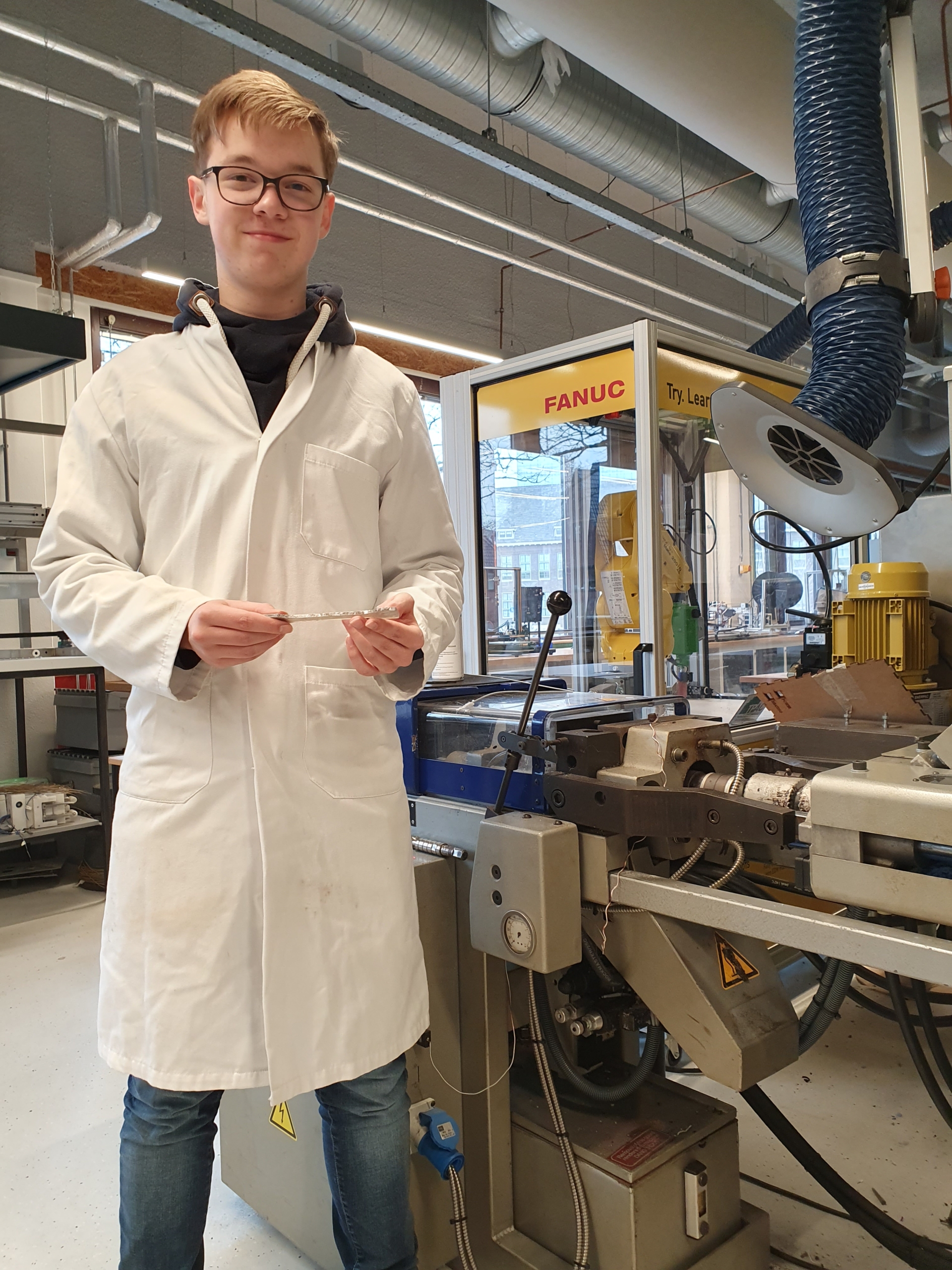

Student works on Polycarbonate recycling

The student Ivar Stokvisch from the Saxion course on Sustainable Chemistry, has worked at TPACs labs on recycling methods for Polycarbonate (PC), supplied by Falco B.V., a company in Vriezenveen that produces outdoor furniture such as bicycle shelters. He looked into the chemical and mechanical recycling, aiming at creating a loop for this stream and starting a second [...]

Webinair “Lightweight Opportunities for Thermoplastic Composites”

On 24th November, TPAC organised the webinar “Lightweight Opportunities for Thermoplastic Composites”, as an educational activity that falls within the WP2 of the Righweight Interreg North Western Europe, a project which goal is to intensify the cooperation between the automotive and the aerospace sectors for reaching environmental and affordability targets. Thermoplastic Composites offer great opportunities for large series [...]

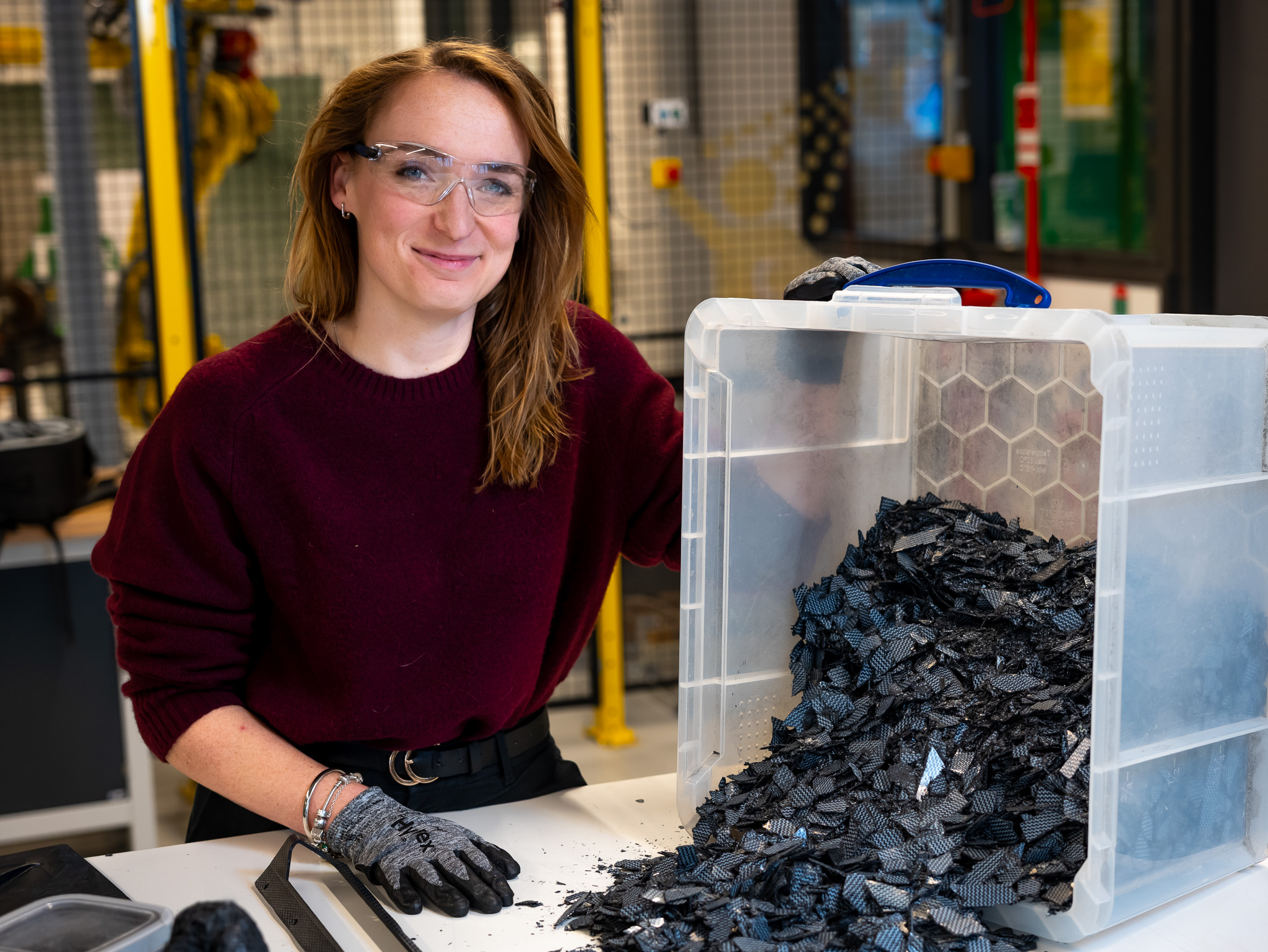

Recycling of air filters

In the past months, TPAC has worked closely together with CIM Fieldlab, Brink Climate Systems and Hogeschool Saxion students looking into the possibilities of recycling Brink's air filters as part of creating a circular business model. The project offered the students a challenging real-life industrial problem to be solved in intense collaboration, under the supervision of Harrie van Bommel, Marco Del Vecchio and [...]

IN THE MEDIA

- Wat hout kan – De basis zijn voor composiet

Houtblad, feb/2021

- Textielbedrijf zoekt toekomst in weven nieuwe composietmaterialen

Kunststof & Rubber, 19/11/2020

- Textiel bedrijf zoekt toekomst in weven nieuwe composietmaterialen

Vraag & aanbod, 16/11/2020

- Rotocraft access panel from recycled carbon PPS – World’s first flying fully recycled thermoplastic composite application in aerospace

Composite Solutions & Technopolymers, Nr. 2 2020 - Wereldprimeur voor TPAC van Saxion met gerecycled vliegtuigonderdeel

Twente.com website, 04/09/2020 - Recycled thermoplastic composite rotocraft access panel takes flight

Composites world website, News post: 27/07/2020 - HOW IT’S MADE – A rotocraft access panel made from recycled carbon PPS

JEC website, News post: 01/07/2020 - Gebruikte vliegtuigonderdelen recyclen

Kunststof & rubber nieuws website, News post: 29/06/2020 - Wereldprimeur: eerste vlucht met gerecycled composiet

OostNL website, News post: 25/06/2020 - Wereldprimeur: Saxion brengt het ‘groene’ vliegen dichterbij

De gelderlander website, News post: 23/06/2020 - Wereldprimeur: Saxion brengt het ‘groene’ vliegen dichterbij

AD website, News post: 23/06/2020 - Wereldprimeur: Saxion brengt het ‘groene’ vliegen dichterbij

De stentor website, News post: 23/06/2020 - Nederlandse methode om koolstofvezels te recyclen blijkt succesvol

Recycling magazine website, News post: 23/06/2020 - Eerste vliegtuigonderdeel van gerecycled composiet ter wereld succesvol getest

BNR niewsradio website, News post: 23/06/2020 - Wereldprimeur Saxion brengt het groene vliegen dichterbij

Luchtvaart nieuws website, News post: 23/06/2020 - Primeur Saxion Enschede, reclclebaar restaafval vliegtuig

Tubantia website, News post: 23/06/2020 - Wereldprimeur rotocraft vliegt met door Saxion ontworpen toegangsluik van gerecycled materiaal

Saxion website, News post: 22/06/2020 - Vliegtuig met gerecyclede materialen, is dat de toekomst?

Duurzaam bedrijfsleven website, News post: 22/06/2020 - Nederlandse methode om koolstofvezels te recyclen blijkt succesvol

Luchtvaart nieuws website, News post: 20/06/2020 - Saxion Enschede zet flinke stap op weg naar duurzaam vliegen

Tubantia website, News post: 18/06/2020 - Productie duurzaam vliegtuig stap dichterbij

Transport online website, News post: 18/06/2020 - Gerecycleerd koolstofvezelcomposiet doorstaat vliegtest

Engineers online website, News post: 18/06/2020 - Productie duurzaam vliegtuig stap dichterbij

Duurzaam ondernemen website, News post: 18/06/2020 - GKN Aerospace’s thermoplastic components flight tested on bell V-280 valor

GKN Aerospace website, News post: 04/06/2020 - Thermoplastic components successfully flight tested on Bell V-280 Valor

Composites World website, News post: 04/06/2020 - GKN Aerospace’s thermoplastic components flight tested on Bell V-280 Valor

JEC Composites website, News post: 04/06/2020 - The state of recycled carbon fiber

Composites World website, News post: 04/09/2019 - GKN Aerospace thermoplastic composites featured on Bell V-280

Composites World website, News post: 20/06/2019 - Twee vliegen in een klap

Go! Mobility Magazine RAI Vereniging, 01/2019 - Visnet wordt stonebag voor Rijkswaterstraat

KUNSTSTOF & RUBBER website, News post: 28/12/2018 - Saxion-student ontwerpt neus veiligheidsschoen van afvalcomposiet

KUNSTSTOF & RUBBER website, News post: 01/11/2018 - TPAC and TPRC develop thermoplastic composites recycling process

Composites World website, News post: 19/10/2018 - Nieuwe onderzoeksfaciliteiten voor composieten in Enschede

Smart Industry NL website - The Dutch ThermoPlastic composites Application Center opens new lab facilities

JEC Composites website, News post: 09/25/2018 - Bulkpolymeren tien keer zo sterk met gebruik van vezels

KUNSTSTOF & RUBBER, 11-12/2017, pp. 6-9 - Nieuw application centre voor thermoplastisch composiet

KUNSTSTOF & RUBBER, 10/2017, pp. 28-29 - Nederlandse onderzoekers geven ‘wondermateriaal’ koolstofvezelcomposiet tweede leven

SCIENTIAS article, 09/2017